GREASE INTERCEPTOR PUMPING IN PHOENIX

Phoenix Grease Interceptor Pumping

Grease Interceptor Pumping Services in Phoenix

The number of food service establishments here in Phoenix, is one of the largest per capita in the USA. It seems that restaurants compose the majority of businesses we see here. Because of this fact, we have grown exponentially along with the food service industry in the field of grease interceptor pumping & cleaning services. We value our reputation as one of the top grease interceptor services company in Phoenix, and we work hard to continue providing the same quality service that earned us our reputation of excellence in the first place.

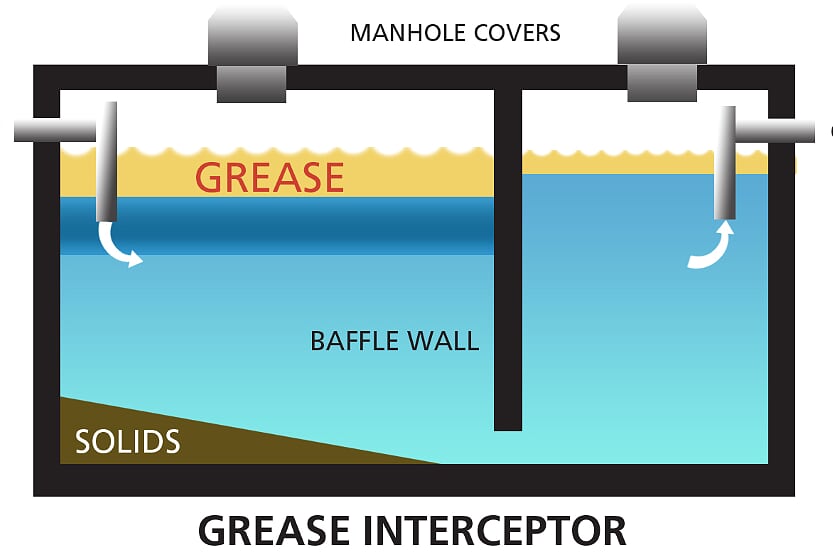

Grease interceptors are an indispensable part of the food servicing industry today. Without that one piece of technology our sewage and water disposal systems would quickly be rendered inoperable due to the sheer volume of fats, oils and greases (FOGS) flooding them out from the countless restaurants and industrial kitchens across the nation. Grease interceptors have been specially designed with many chambers and traps to contain this waste so that this disaster will never happen.

The basics of grease interceptor services

Scheduling the cleaning and servicing of grease interceptors

The first step in determining the schedule of cleaning and servicing a grease interceptor is to figure how much greasy and oily food waste will need to be processed. Of course, fried food will produce much more waste than baked goods, and that’s one factor. The next determining element is the size of your grease interceptor reservoir. The production of greasy food with a smaller capacity interceptor will require more frequent cleaning than one with a larger capacity.

Taking these variables into consideration, an industrial kitchen could suffice with a semiannual pumping and cleaning, or may require a more rigorous schedule of monthly maintenance. But the primary target is to never let the system exceed 25% capacity of all FOGS (fat, oil, grease, solids).

25% The Magic Number

Research has indicated that when a grease interceptor reservoir reaches FOG levels of 30%, the risk of any overflow or leakage of waste materials increases greatly. Since then, it has become an industry standard to never allow FOG levels to exceed 25% of capacity. In this way we avoid the 30% threshold altogether.

Keep in mind that while 25% of a 750 gallon tank is much less quantity than 25% of a 3000 gallon grease interceptor system, the rule still applies due to the fact that 30% remains the threshold regardless of how big system is. This rule is in place to stay well within the local authorities regulations.

But What About Small Indoor Grease Traps?

Smaller, neighborhood restaurants and grills require only the smaller grease traps, usually located below the kitchen sink. These typically are in the capacity range of 5 to 50 gallons. While they are very small, relative to their large grease interceptor cousins, they actually need more frequent pumping and cleaning, because of the fact they are so small.

Scheduled Maintenance and Service for Outside Interceptor Traps

Outdoor grease interceptors can be found buried behind the establishment or even below the parking area. The larger, more complicated grease interceptor systems naturally require more room than any indoor grease trap. Therefore, it is much more practical to install a system with the capacity of 750 to 5000 gallons in such a location to accommodate the logistics of the more sophisticated plumbing system such a large system requires. It makes it easier to service as well.

What happens when your grease trap or interceptor has problems

Hydro-Jet Water Pumping at Your Service!

Pumping out the many chambers of your grease interceptor system is just the beginning. After all the liquids have been pumped out there is still many layers of greasy, sticky grime at the bottom, in the nooks and crannies and sticking to the walls of the tank. This must be removed or the efficiency of your grease interceptor system will be greatly reduced.

We employ the use of hydro-jet pumping to blast any last remnants of the greasy remnants away from all areas, especially near the plumbing openings that lead to the successive chambers. Utilizing a pressure of up to 3500 PSI, this method absolutely leaves your interceptor system just like new!

Affordable & Reputable Grease Trap Services